The inentec opportunity

Deploying proven Technology Readiness Level 9 (TRL9) waste-to-energy technology,

with an initial focus on the Middle East & North Africa (MENA) region.

Background:

On the 6th June 2025, HYDROGEN UTOPIA INTERNATIONAL PLC announced that it had signed a binding outline agreement with InEnTec Inc. of the United States, covering the Middle East & North Africa (MENA) region. This outline agreement provides for an exclusive negotiation period of 180 days, from the day of signature of the Outline Agreement, to negotiate a proposed access to exclusive licences for InEntec’s advanced TRL9 PLASMA ENHANCED MELTER (PEM) waste-to-hydrogen technology across the MENA region. PEM technology can now be proposed for deployment in Gulf Cooperation Council countries (GCC), HUI’s primary focus.

Intorduction to InEnTec Technology:

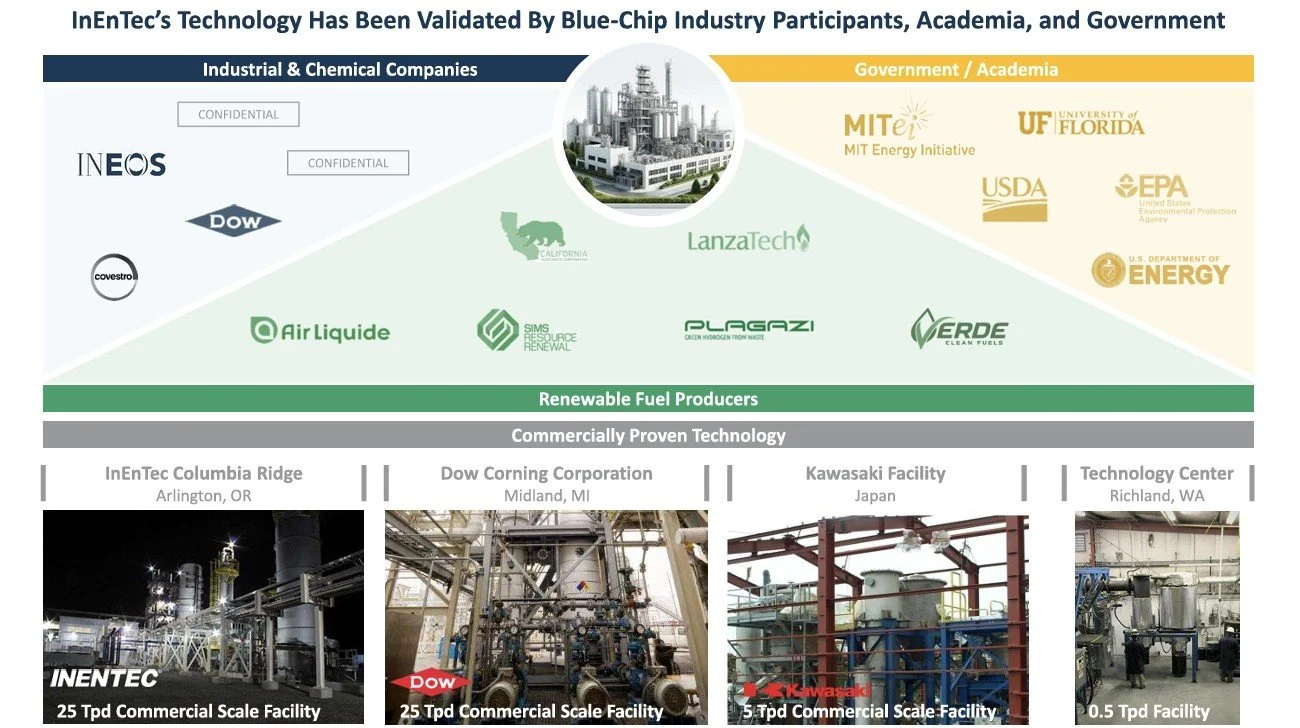

InEnTec's Plasma Enhanced Melter (PEM) system was developed in collaboration with the Massachusetts Institute of Technology (MIT), and has been operating successfully for over 13 years at full commercial scale. It can process a wide range of complex waste streams, including mixed plastics, tyres, and hazardous waste, to produce clean hydrogen and capture carbon dioxide. It was originally designed as a hazardous waste facility but is now repurposed as a hydrogen production system. This presents a highly effective and sustainable solution for industrial decarbonisation and waste reduction.

GCC Strategy:

The first phase of deployment will target the Kingdom of Saudi Arabia and the United Arab Emirates, along with Oman, where there is a growing demand for low-carbon construction materials, specifically steel and concrete, as well as carbon capture and utilisation solutions (CCUS) in the oil and gas industry, particularly for Enhanced Oil Recovery (EOR). The InEnTec Technology, when deployed with Gas Water Shift (GWS), doubles the hydrogen output and produces significant quantities of high-grade CO2 for EOR.

harnessing The Power of Plasma

Plasma is an ionised gas formed when an electrical discharge passes through it. Plasma torches and arcs convert electrical energy into intense heat, with temperatures reaching up to 10,000°F (5,538°C). The plasma technology breaks down waste materials into their elemental components, forming a synthesis gas (syngas). The syngas yields hydrogen and other valuable products whilst any inorganic materials are melted into a non-hazardous, glassy slag that can be used for construction. The PEM unlocks the greatest amount of energy from hard-to-abate and hazardous waste, removing it from the system entirely, whilst recovering its latent value.

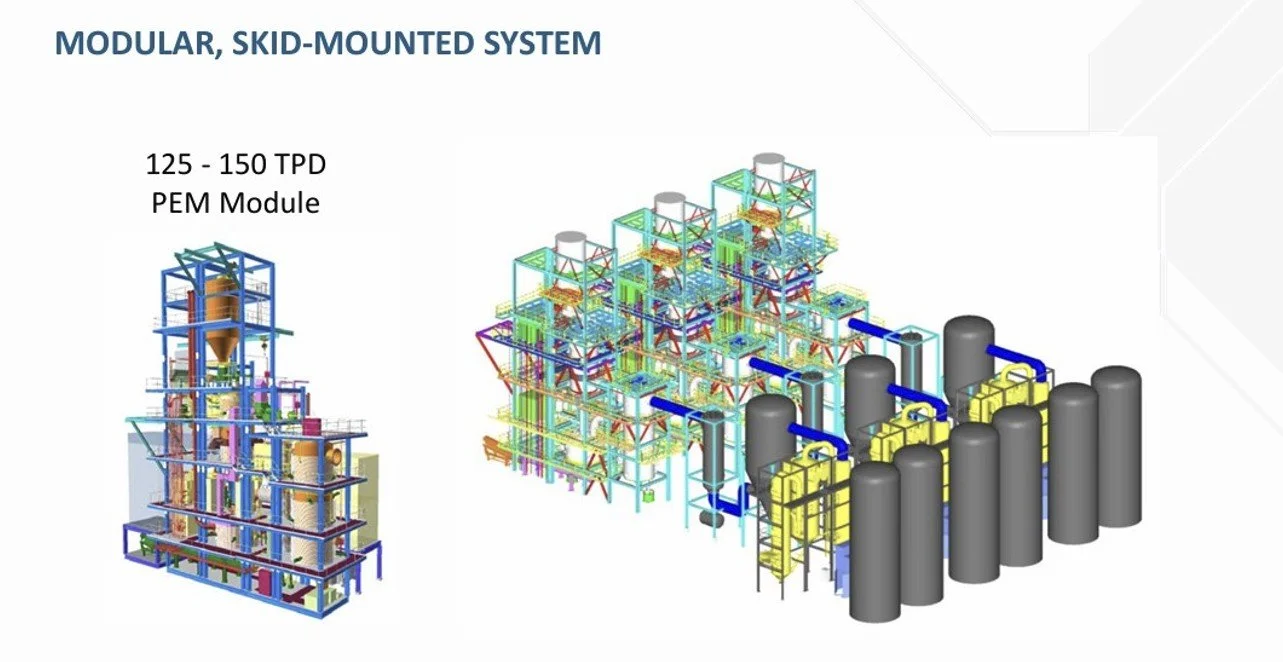

modular design

The PEM has been engineered as a standardised 25 - 150 tonnes per day unit, allowing for the linking of multiple modules in parallel to create capacity across a continuous range.